Pedestal Rock Breaker Boom System

Stationary Pedestal Rock Breaker Boom System for Sale

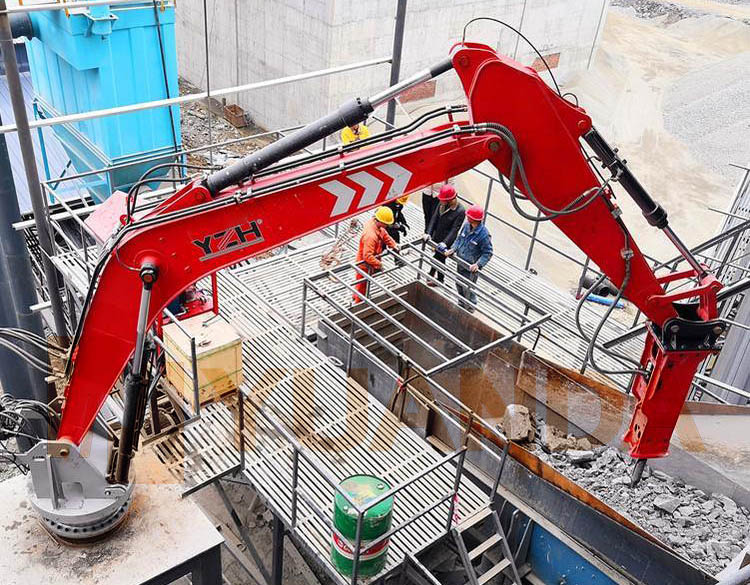

Pedestal Rock Breaker Boom Systems are designed specifically for stationary primary crushing plants as well as mobile and portable plants. These rock breaker systems work in unison with impact, jaw and gyratory crushers, assisting these crushers to achieve their rated capacities.

Horizontal Reach: 3~18m

Vertical Reach: 2.5~10m

Hammer Mass Weight: 250kg~4000kg

Lifting capacity at maximum reach: 1 2 2.5 3 Ton(tonne)

Models: YZH WHB

Power supply: 380v 50Hz 3Phase

Control method: joystick control, wireless remote control, operator cab control

Ambient temperature: -20~40℃

Rock breaker boom system supplier type: China manufacturer

Pedestal boom system price: $20,000~$50,000

Stationary Pedestal Rock Breaker Boom System for Sale

Stationary Pedestal Rock Breaker Boom System Design

Our range of Pedestal Boom Systems are designed for use on crushers for the purpose of breaking oversize stone or rock material or raking bridged material. They are also used for other applications such as breaking oversized material on the grizzly screen.

The range consists of several different models with horizontal reach of 3.5m to 12m (12’ to 39’), catering for a variety of applications from the standard quarry and iron mining operations such as jaw crusher or small grizzly to the large heavy duty stone crusher and grizzly operations.

For environments where overhead space is limited we offer pedestal jib boom with compact structure, which allows the boom to fold and manoeuvre in the confined space while still having the reach required. The pedestal boom range is available in 180° or 360° slew, manufactured from the high quality steel materials to withstand the toughest of applications; the range is built to ensure safety and increased production.

Our stationary rock breaker booms are installed worldwide including the most extreme working environments of -45C to +40C. Our fixed rock breaker boom systems are superior quality and built to withstand the destructive nature of their intended application.

When production targets are very important and down-time due to crusher blockages is a problem, you can rely on us to provide cost-effective rockbreaking solutions! The installation of a hydraulic rockbreaker boom system greatly improves productivity by breaking blocked oversize material quickly and safely and solving bridging problems by raking material into the crusher.

Pedestal Rock Breaker Boom System Features

Model No./Series: B300 C350 C400 C450 C500 C550 C600 D300 M630 M550 M440 XL940 XL1400 XL1200 XM750 XM600 XM500 XR600 XR700

Input power: 18 30kw 35 36 40 45 50 55kw

Hydraulic power: 25 40 50 75 100 125 Horsepower

Operating weight: 5000kg 6000kg 7000kg

Maximum boom reach: 3m 3.5m 4m 5m 6m 7m 8m 9m 10m 11m 12m 13m 15m

Horizontal reach: 20 24 28 30 32 34 35 36 38 40 42 45 ft/feet

Vertical reach: 16 18 19 20 21 22 24 25 27 28 ft/feet

Lifting capacity at maximum reach: 1000 2000 2500 3000 4000 5000 6000 lbs (pound) kgs

Swing rotation angle: 170° 180° 330° 360°

No. of jib arm: 2

OEM/ODM: Yes

Hammer rod tool diameter: 68mm 70mm 75mm 80mm 85mm 100mm 125mm 135mm 140mm 150mm 155mm 165mm 175mm

Light weight, compact modular design, easily built foundation

Full electrification

Heat treated conical pins

Joystick control

Compatible with heavy duty rockbreakers

Automated rockbreaking systems

Stationary rock breaker mounting design: 1) Mounted on round shock absorbing pedestal, 2)mounted to mobile crusher, 3) mounted on floor to side of jaw, servicing the jaw, feeder and dump chute, 4)mounted on a hydraulically raised platform, mounted on a bridge type platform over hopper, 5)mounted on a lattice frame tower

We offer total rockbreaking solutions for our clients. Our heavy duty rockbreaker booms are suitable for permanent rock breaking in arduous applications. A pedestal rockbreaker boom is the safest way to manage bridging, build ups and oversized materials. Our stationary rock breaker boom systems enhance the safety, productivity and profitability of crushing applications in mines and quarries worldwide.

Rockbreaker Boom System Used For Primary Crushing Of Aggregate On Grizzly Screen

Radio Remote Control Automated Rockbreaking System Pedestal Rock Breaker Boom System

Rocker Breaker Boom System with Pedestal Mount for Primary Crusher

Stationary Type Pedestal Rock Breaker Boom Systems for Sale

Pedestal Boom Arm System with A Rammer Hydraulic Breaker Hammer

Small Portable Rockbreaker Pedestal Boom Systems

Underground Mining Rock Breaker Boom System at Tunnel

Small Mobile Pedestal Rock Breaker Boom Systems Mounted On A Wheeled Trolley Cart On Railway

Bucket Type Stationary Manipulator Arm Pedestal Boom Rock Breaker Excavator

Technical Parameter of Heavy Duty Stationary Pedestal Rock Breaker Boom System

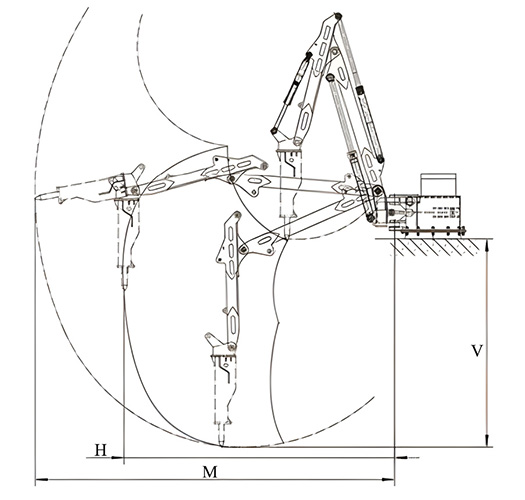

RANGE OF MOTION

*Custom options available to meet customer specifications and local construction conditions.

Stationary Rock Breaker Boom Systems Specifications

Name | Pedestal Rockbreaking Boom System |

Weight | 1400kg 6800kg 23000kg |

Input power | 30kw 45kw 50kw |

Maximum reach | 5.2 m 10m 18m 20m |

Nominal horizontal reach (H) | 3.5m~16m |

Nominal vertical reach (V) | 3m~18m |

Excavation depth | 3~14m |

Number of joints | 2 or 3 |

Swing rotation angle(degree) | 170° Pedestal Swing Post 330° Indexable Turntable |

Base dimensions | 0.95 x 1.2m |

Hydraulic breaker tool diameter | 3" 4" 5" 6" 7" 8" |

Impact rate for rock breaker hydraulic hammer | 200bpm~900bpm |

Voltage | 220V/240V/380V/400V/415V |

Application | Jaw Crusher Blockages Impact Crusher Blockages Blockages and build-ups Gyratory Crusher Blockages Grizzly Blockages Grates Demolition Metallurgical |

*Pedestal boom rock breaker’s specifications are subject to change without notice. These series are configured with a turntable slew bearing swing base as standard.

Different Types Of Pedestal Rock Breaker Boom System

Specialized in the design and manufacturer of the rock breaking machines and underground mining equipment, we offers a comprehensive range of fixed rock breaker booms to enhance the safety, productivity and profitability of crushing operations in mines, quarries and stone crusher plant around the world. YUANDA is a unique pedestal rock breaker boom supplier, delivering complete rock breaking equipment packages to meet customer’s specific needs.

Light duty Rock Breaker Boom

The China rock breaking booms is a light weight, multipurpose boom to be typically used in quarries, next to primary crushers or mobile crushers to clear blockages and bridging. They can be operated directly by the joystick valve levers or by using a radio radio control.

YUANDA small series light weight rockbreaker booms are typically mounted on stationary crushing plants, and used in combination with a small range breaker.

Mobile Rock Breaker Boom System

The mobile rockbreaker boom is a light weight, multipurpose, portable rockbreaker boom that has been designed to be mounted on mobile crushing plants and impact crushers to clear blockages and bridging.

Different from the rocker breaker boom with pedestal mount for primary crusher, this portable mobile rockbreaking booms feature a low-profile design that maintains the crusher´s low transportation height, can be installed on many crushers of different brand. For instance, it can be mounted on a LT3054 Metso crusher, MC125Z Kleemann crusher, Gipo mobile crusher, PC1265J Hartl crusher, Lippmann L3252, Terex pegson crusher, finlay jaw crusher and so on.

Heavy duty Pedestal Rock Breaker Boom

With a long reach, 360° rotation and high breaking power, the boom system rock breaker is ideal for demanding applications such as gyratory crushers in mining and quarry applications, and grizzlies in mining.

The fixed rock breaker boom system for jaw crusher and impact crusher can be operated directly by using a wireless radio control. An upgrade is available to incorporate Teleoperation System, enabling automatic remote operation via the plant 5G network and in-built collision prevention with programmable automated movements such as park and deploy.

Boom swing with slew ring enables wider coverage, easier service access and constant swing torque. Hydraulic pedestal rock breaker boom system is also available for arctic conditions at temperatures down to -43°C, for tropical conditions, for use at high elevations and for explosive environments.

China hydraulic pedestal rockbreaker boom system is designed for gyratory cone crusher or used for primary crushing of aggregate on grizzly screen. As a fixed rock breaker boom systems supplier in China with over 20 years experience, we are dedicated to design the right pedestal rockbreaking boom system for your needs. Contact us now for more information.

Applications of Rock Breaker System

China pedestal rockbreaker boom system are mounted at primary jaw, impact and gyratory crushers and stationary grizzlies. They are used for crushed stone, hard rock and ore reduction, and C&D recycling applications. The static rock breaker boom systems are designed for stationary primary crushing plants as well as mobile and portable plants.

•Stationary rock breaking

•Breaking bridged rock

•Construction and demolition recycling and sorting

•Industrial recycling systems

•Concrete breaking and concrete recycling

•Asphalt recycling

•Bulk material handling

Our hydraulic pedestal rock breaker boom systems provide the means to maximize the rated capacities of crushers. They also provide a safer method to alleviate blockages at the crusher caused by oversized, wedged and bridged materials.

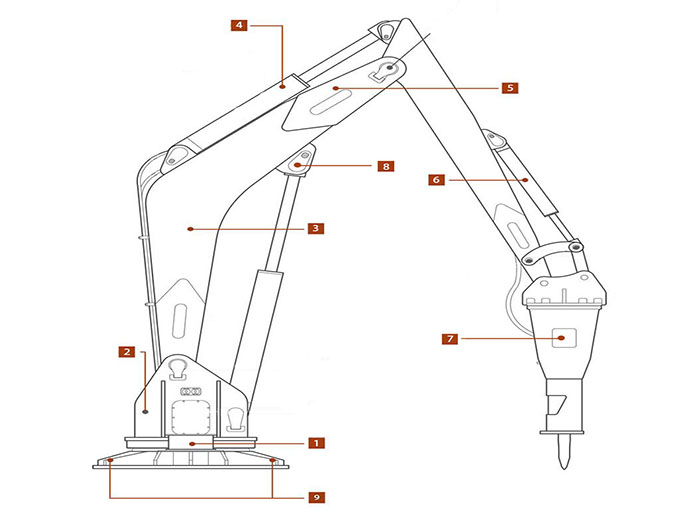

Spare Parts, Components & Accessories for Pedestal Rock Breaker Boom System

Fixed rockbreaker boom systems are designed and built to withstand the destructive nature of their intended application. They are manufactured with the use of components or fittings that exceed standard design requirements and therefore ensure a long service life and minimum maintenance requirements for the stationary manipulators with a hydraulic breaker hammer.

1. heavy duty 360 degree slew ring and pinion system.

2. Electro-hydraulic proportional control valve

3. Boom with high-strength steel frame

4. Oversize long-stroke high-pressure cylinders

5. Special torsion reinforcements

6. Heavy duty cylinder with hard chrome rods

7. Rock hammer

8. Hard steel pins & bushes. Hard wearing and long lasting

9. Oversized mounting base

Heavy Duty Constructed Boom Arm

YUANDA’s biggest pedestal boom system breakers are designed for high performance in large capacity crushers. They are constructed with massive reinforced steel box sections. An excavator style arched main boom sections and tapered dipper stick are reinforced at all critical points of the hydraulic manipulator breaker.

360° Swing Table

The stationary rockbreaker system features a ball-bearing swing gear assemblies and hydraulic motors with planetary gear drive for maximum horizontal distribution of loading forces.

Heavy Duty Cylinders

YUANDA hydraulic cylinders of stationary rockbreaker boom system are designed to provide superior strength and extended service life under arduous conditions. All cylinders are specifically built for rock boom applications with special rod coatings and high strength rod end attachment. This construction heavy equipment is also named hydraulic manipulator arm rock breaker.

Hydraulic Power Pack Unit

The Power Pack comes with complete electrification to deliver all the power you need for the fixed mechanical arm boom attachment. It features easy and reliable installation – just connect the electricity and turn the switch. Power packs are sized to match the specification of the chosen attachment.

Interconnect Network and Smart Monitoring System

New intelligent remote monitoring system, based on the principles of the Internet of Things, to prevent equipment obsolescence and keep high performance. The internet remote control system consists of a device equipped with camera, display monitors and 4G/5G technology for a wireless connection to the network, to be mounted on the stationary rockbreaking equipment, and a cloud-based web platform you can access from mobile phone devices (with an app) or from PC, that lets you view the data transmitted in real time by each installed hydraulic rock breaker boom system: working hours, working position in space, GPS position, hydraulic oil temperature, ambient temperature and more. What’s more, this automation system for pedestal rockbreaker booms can provide collision avoidance and remote operation functionality.

Support Tower

A steel support tower can be used to support construction heavy equipment. Designed to ensure structural integrity and to gain maximum capacity, they may feature a walkway and ladder.

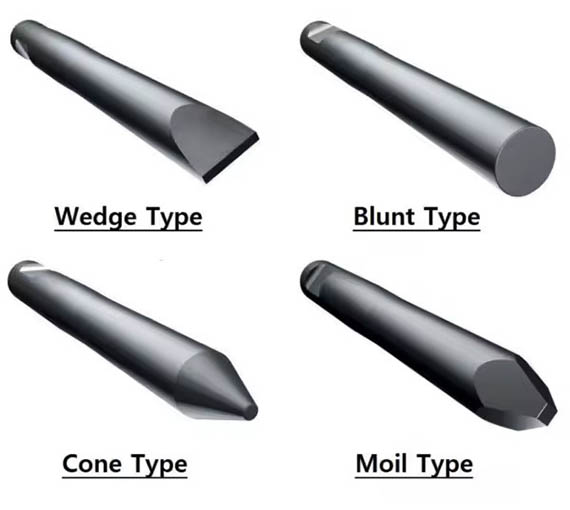

Tools

We offer a choice of tools and lengths for all rock breakers, the diameter and length of the hydraulic hammer drill rod tools can be customized to comply with your crushing plant technical specifications.

Other pedestal rock breaker boom system spare parts and accessories include: hydraulic rock breaker hammer, wireless radio remote control system, fully automatic greasing system(automatic lubrication device), operator cabin, hook, grab, bucket attachment, mechanical quick coupler, hydraulic motor, pump, return filter, oil level switch, hour meter, pressure filter and oil cooler, tools(Blunt/Chisel/Moil), extension carriage.

Installation and Commissioning of Pedestal Rock Breaker Boom System

We offer you a complete pedestal mounted rock breaker boom system package specific to your requirements: Not only provide the bock breaking equipment including rock breaker boom, hydraulic power pack, operating controls, hydraulic breaker and supporting steelwork, but also can be responsible for pedestal rock breaker boom system installation, commissioning, training, maintenance and technical support. We are a customer-service-focused company that you can count on to provide service before and after the sale. Our experienced engineers and customer support team are always on hand to provide valuable advice on the most suitable stationary boom breaker products for your application, as well as pedestal rock breaker boom installation, commissioning and training support and after sales maintenance advice.

How to Select The Right Type of Pedestal Rock Breaker Boom System?

Generally, there are 4 things you shall consider before selection and buying a pedestal boom system. Pedestal mounted hydraulic boom systems are typically installed above crusher inlets or hoppers and grizzly screens to minimize downtime and avoid damage caused by oversize rock blocking chutes or crusher inlets.

To ensure optimum performance, it is important to consider the following before purchasing a new rock breaker boom system:

1-A correctly sized hydraulic rockbreaker hammer

2-The hydraulic stationary rock breaking boom system size and reach

3-Installation position, elevation and working slew angle of the pedestal rockbreaking boom system

4-Safety systems, automation, remote operation and spare parts

These tips for purchasing a pedestal rock breaker boom system from a fixed rock breaker boom supplier means a lot for the invest

ent, it is best to consult our professionals prior to purchase or installation to confirm the most suitable model for your application.

Pedestal Rock Breaker Boom System Supplier/Manufacturer in China

Pedestal rock breaking boom systems is designed for mining and crushing application. YUANDA is a fixed rock breaker boom system supplier, offering stationary rockbreaker boom assemblies to match any job. We have exported the stationary pedestal rockbreaker boom system to many countries, such as Netherlands, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Middle East, the United Kingdom, EU, and more. All our pedestal boom rock breakers are CE certified. Our hydraulic rock breaker boom system series are engineered for a precise duty level that is ideal for a mine crushing plant. Every model is manufactured to the high standards of performance and reliability. Would you require a custom rockbreaking solution, we will design and engineer a rock breaking booms systems that precisely fits your needs. Contact us now to discuss your requirements and get a pedestal rock breaker boom system price.

Related Products

China fixed type pedestal rock breaker boom system or rockbreaker boom system is a static, pedestal-mounted, hydraulic powered rockbreaking equipment mounted over the grizzly, primary jaw, impact, gyratory crushers, mobile and portable crushers for oversized rock breaking in quarry and mining plant.

Rock breaker boom hydraulic stationary manipulator arm is a fixed mechanical arm fitted with hydraulic breaker hammer. This rock breaking equipment is used in mining, quarry, aggregate industries and stone crushing plant to manipulate large rocks.

We supply hydraulic rock breaker tools for hydraulic hammers (hydraulic rock breakers) and heavy demolition tool bits. Sorted as breaker chisel, blunt, moil point, and cone type, the working tool is a key attachment, accessory and spare part fitting in a pedestal rock breaker boom system, which is used for rockbreaking, crushing at mine and quarry industry.