Overhead Conveyor System

Towline Conveyor System

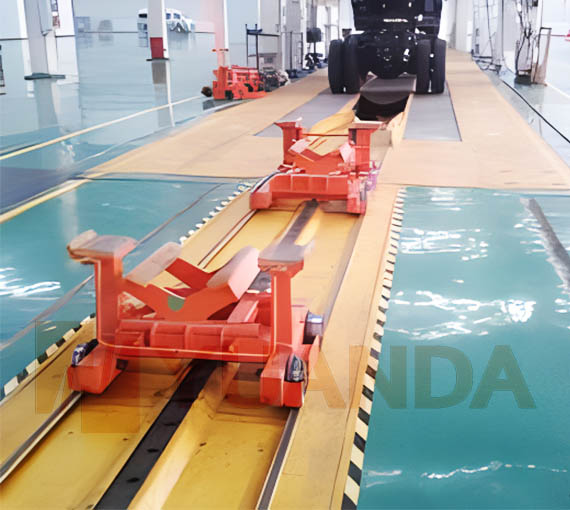

Tow Line Conveyor is a floor mounted chain conveyor system, pulled by the chain that allows to tow many carts at the same time, on which the products are moved.

Chain carrier pitch:300mm 400mm 16”

Max. Temperature: 250°C

Max. Load per Trolley: 250kg

Max. Load per Loadbar: 500kg

Models: Tow line conveyor

Horizontal bends: 750 mm radius at 15°/ 30°/ 45°/ 60°/ 90°

Drive unit: Caterpillar drive

Speed: Variable speed (custom)

Power supply: AC-3Phase-220/380/400/415/440V-50/60Hz

Towline conveyor system manufacturer: China supplier

Towline conveyor system price: $8,000~$60,000

Towline Conveyor System

Towline Conveyor System For Sale

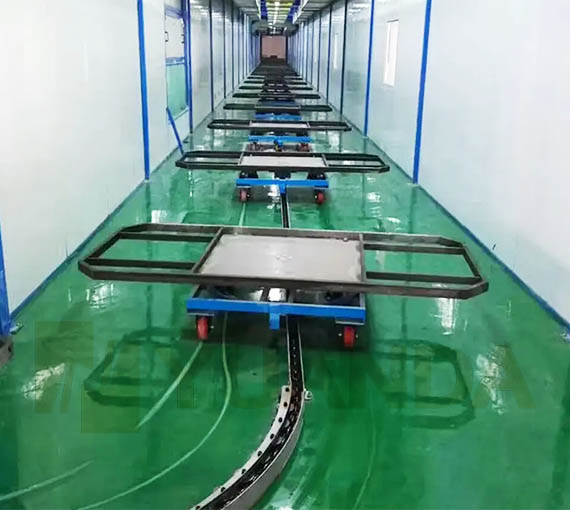

Tow Line Conveyor System is an underground conveyor, installed on ground level, pulled by a robust chain that allows to tow many carts at the same time, on which the products are transferred. It is also known as ground tow cart conveyor. Each car can have different dimensions and shapes according to the type of products to be moved.

The towline conveyor system utilizes mobile carts, normally with a rotating top, onto which the item to be conveyed is placed. A variety of floor-mounted conveyors are used to propel the cart through the process, depending on the loading, speed and preferred configuration.

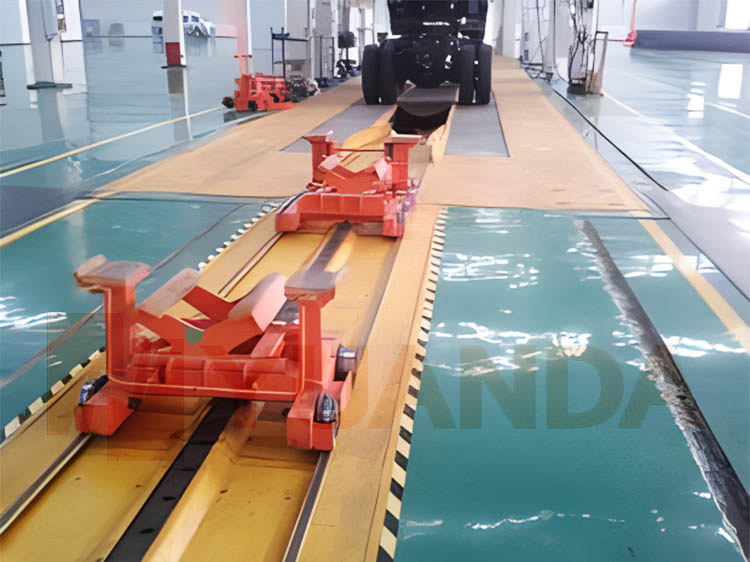

The Towline Conveyor system can be designed with on-floor or in-floor tracks. On-floor conveyors are attached to the floor surface without trenching. If mounted above the floor, provisions must be made where the cart crosses over the drive unit.

Simple in design and rugged in construction, the towline conveyor system is used for assembly plants, finishing lines, wood industry and distribution centers.

Features of Towline Conveyor System

Model number: X348, X458, X678, 150 200 206 240 250 300 350 400

Loading capacity: 5ton 7ton

Cart spacing: as requested

Chain model: UH-5075 WF-350 WF-400 XF400 QXT150 QXT200 QXT250 QXT300

Chain pitch(spacing): 150mm 200mm 250mm 300mm 350mm / 6” 8” 10” 12” 14”

Horizontal curves: 600mm 800mm 1000mm

Degree: 90° / 45° / 30° / 15°

Radius: 600mm 700mm 1000 mm 1200mm 1500mm

Electric control system with frequency inverter

Cart accumulation

Heavy-duty load capacity

Power and free towline conveyor system, at staging and queue areas, carts can be indexed and accumulated as required.

Cars can be customized to different application.

Standard 4-wheeled cart is propelled by a drive chain.

Mobile workstations with lift/lower capabilities and product rotators

Simple four-wheeled transport dollies

Drag Chain Conveyor using forged rivetless chain

These towline conveyors are a more cost effective approach to conveying dollies.

The floor conveyor track system can be mounted “in floor” or “on floor” with minimal cross section height.

Towline track can be in-floor or on-floor mounted with minimal cross section height.

Top platens can be custom designed based on size, shape and weight of the item being conveyed by the towline floor conveyor. Platens can be rotated manually or automatically for close packing in accumulation zones.

Reliable conveyor chain used with ball bearing wheels instead of “link” chain to reduce maintenance.

Loop system on ground floor.

Automotive Running, Encoded chain to track carts

Automatic drive/chain lubrication

Low-friction roller chain turns

Remote controls diagnostics and monitoring

software integration, RFID tag integration

In-Floor Tow Conveyor features inline conveying for roll handling and progressive assembly, palletizing and packaging. An optional automatic load and unload feature is also available

Towline Conveyor Accessories, Components and Inverted Power and Free Conveyor Spare Parts are available.

Applicable industries: Enclosed track towline conveyor for powder coating line, spray painting line, automobile industry, workshops, manufacturing plant, automotive industry, paint finishing and assembly lines, surface treatment industry, etc.

Towline ground track system on floor can be custom designed to accommodate your specific paint line or assembly line requirements.

Technical Data & Technical Specifications of Towline Conveyor System

Chain carrier pitch: 3inch / 4inch / 6inch Max. temperature (surrounding): 250° C Max. load per 4-wheeled cart: 200kg 250kg 1000kg 3000kg Max. load per car/wagon: 400kg 500kg 3T Standard length, straight profile: 3.000 mm - equipped with flanges Trolley bearings: Closed and greased for low maintenance | Horizontal curves: Degree: 90° / 45° / 30° / 15° Radius: 600mm 700mm 1000 mm roller turn Special dimensions on request. Drive unit: Caterpillar chain drives Tension unit Custom platen with rotator Switching gate: Pneumatic blade version (without separate transfer sections). R = 700 mm

|

Accumulation stops: Pneumatic version Lubrication: Pneumatic fog or Pneumatic point lubrication – automatic Accumulation features: In line, 45° and parallel (90°) Applications: automotive, surface finishing, manufacture plant, distribution, general manufacturing, production line. |

*Heavy duty towline conveyor system specifications may be subject to change without notice. This type of conveyor consists of an embedded track with trolleys carried by chain. Therefore, they require two tracks for a straight run, a live track and a return track. Chain on edge towlines are more flexible as they can make any curve desired.

Applications of Towline Conveyor System

We build Towline conveyors, which are embedded in the floor or are mounted on the ground. They are known as in-floor chain conveyor system and on the floor towline conveyor system. Towline conveyors are a material handling system that uses a towline (usually a chain) recessed beneath the floor to pull wheeled carts along a fixed path. Floor towline conveyor system can be used in a wide variety of applications where it is advantageous to carry products on mobile carts, trolley or dolly. Some products like large four-legged furniture items are considered “unconveyable” due to their shape, configuration or size. An inline tow cart conveyor system would be an optimal solution.

The towline conveyor system is designed for surface treatment industry, finishing system, automotive industry, assembly operations, wood industry, workshops, warehousing, delivery system, distribution and sorting, industrial paint lines, timber factories, finishing and processing systems, assembly operations, parts transfer systems, sorting, storage and retrieval, transfer and transport, order picking, pallet handling, drum handling and so on.

We have many different models of towline conveyor system for sale, contact us online now for more details.

Towline Conveyor Manufacturer in China

YUANDA is a towline conveyor system supplier and manufacturer in China. We offer surface finishing systems, serving the wood, metal and plastic industries. Our company has integrated the finishing conveyor technology with product transport systems, giving the customer bespoke solution to their paint line. We can custom design, manufacture and supply the complete towline conveyor systems, including simple or sophisticated electrical controls, to suit your production requirements. We also provide the complete software and control systems and monorail towline conveyor installation service, maintenance and training on a turnkey basis. We have exported to many countries including: Saudi Arabia, Australia, European, United States, Canada, Indonesia, Mexico, Chile, Peru, UAE, Malaysia, Middle East, the United Kingdom, EU, etc. Contact us now for your towline conveyor design.

Related Products

Overhead hanging garment conveyors are a premium garment handling, storage, retrieval, transport, delivery, sorting conveyor system. The monorail systems are used for uniform and clothes in laundry, factory, warehouse and production line.

Automated Electrified Monorail System(EMS) is an overhead conveyor system which contain individually motorized carriers that draw energy from an aluminum track mounted bus bar and transport pallet loads throughout automotive assembly line.

Either enclosed track or I beam type, manual overhead conveyor system is a hand push-pull monorail trolley conveyor, used for spray painting, powder coating line, assembly line, carton, garment, surface treatment, automotive industry, and finishing system.